The 900 AC drive is a versatile industrial fan and pump drive that saves time and resources on installation and programming while maximizing efficiency for peak energy savings and the return on your investment.

The 900 AC drive is a versatile industrial fan and pump drive that saves time and resources on installation and programming while maximizing efficiency for peak energy savings and the return on your investment.

3-7 Working Days For Standard Series

High performance frequency inverter

1AC 220~240V / 0.75~15KW

3AC 220~240V / 0.75~200kW

3AC 380~460V / 0.75~560KW

V/f, Vector speed control (IMSVC) of asynchronous motor,Vector speed control (FMSVC) of synchronous motor。

| Item | Specifications | |

| Basic Functions | Motor Control Mode | V/F control |

| Vector speed control (IMSVC) of asynchronous motor | ||

| Vector speed control (FMSVC) of synchronous motor | ||

| Maximum Frequency | Vector Control:0~500Hz V/F Control:0~500Hz | |

| Carrier Frequency | 0.5kHz~16kHz; the carrier frequency will be automatically adjusted according to the load characteristics. | |

| Input Frequency Resolution | Digital Setting: 0.1Hz | |

| Analog Setting: 0.01V corresponding maximum frequency ×0.1% | ||

| Control Mode | Open Loop Vector Control(SVC), V/F Control | |

| Startup Torque | 0.5Hz/150%(SVC) | |

| Basic Functions | Speed Range and Precision | 1:100(SVC);±0.5%(SVC) |

| Overload Capability | 150% rated current 60s,180% rated current 3s | |

| Torque Boost | 0.1%~30.0% | |

| V/F Curve | Line Type、Square Type | |

| Acc. / dec Curve | Straight line or S curve acceleration and deceleration mode | |

| Acceleration and deceleration time range between 0.0 to 500.0s. | ||

| DC Brake | DC Brake Frequency:0.00Hz to maximum frequency. Brake time: 0.0s to 36.0s | |

| Multi-speed Running | It can realize at maximum of 4 segments speed running via the control terminal. | |

| Built-in PID | It is easy to realize process-controlled closed loop control system. | |

| Over-voltage/current Stall Control | It can limit the running voltage/current automatically and prevent frequent over-voltage/current tripping during the running process. | |

| Motor Over-temperature Protection | Acceptable motor temperature sensor input (PT100, PT1000) | |

| Timing Control | Timing control function:set time range 0.0~6500.0Min | |

| Bus Support | Support Site Bus:Modbus | |

| Protection Function | It can implement power-on motor short-circuit detection, output phase loss protection, over current protection, over voltage protection, under voltage protection, overheating protection and overload protection, which can be turned on or shielded as required. | |

| Running | Running Command Source | Operation panel reference, control terminal reference, and communication reference |

| Target Frequency Source | Digital reference, analog signal reference, multi-segment speed reference, PI control reference, and communication reference | |

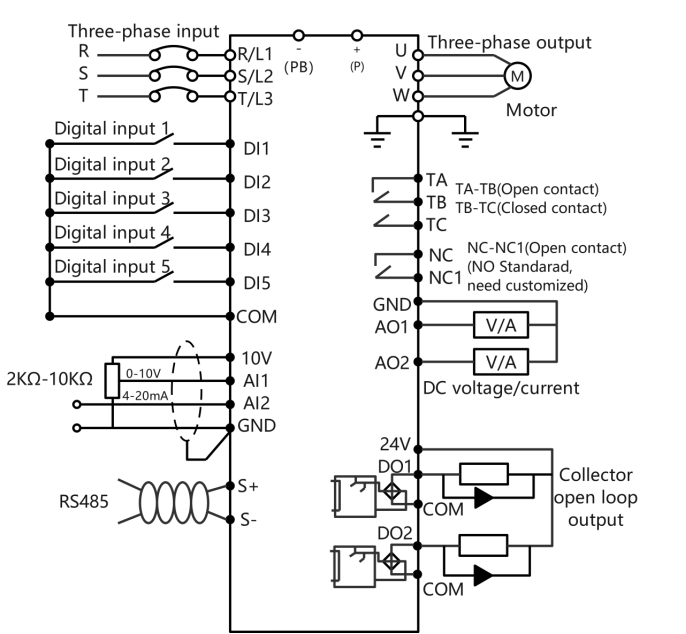

| Control Signal Input Terminal | 5 digital input; | |

| 2 analog input,support 0~10V、4~20mA、0~20mA、20~0mA、20~4mA and 10~0V signal | ||

| Control Signal Output Terminal | 1 relay output, 2 analog input. | |

| 2 analog output,support 0~10V、4~20mA、0~20mA、20~0mA、20~4mA and 10~0V 0~20mA signal | ||

| Environment | Using Place | Indoor, and be free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. |

| Altitude | 0~4000m;Derating use when more than 1000m (decrease by 1% per 100 meters) | |

| Ambient Temperature | -10 ℃ to +40 ℃ (Derating use when under ambient temperature of 40 ℃ to 50 ℃) | |

| Humidity | Less than 95%RH, without condensing | |

| Vibration | Less than 5.9m/s (0.6g) | |

| Storge Temperature | -20℃~+60℃ | |

| IP Level | IP20 | |

| Pollution Level | PD2 | |

| Power Distribution System | TN, TT | |

General type three-phase 380V terminal wiring diagram: